WE'RE THE BEST AT WHAT WE DO

Minate Connecting Dots granulation portfolio includes R&D systems for small production volumes as well as production scale systems

RAPID MIXING GRANULATOR

- Volume – 50ml to 1500 L

- Scale-up with equivalent Geometric, Kinematic & Dynamic similarities.

- The agitator blade with its high shear and compaction guarantees effective granulation.

- The chopper prevents excessive granule growth and distributes the granulation fluid throughout the product.

- Powder conveying integrated systems for material charging.

- Manually , fully automatic operations available.

FLUID BED DRYER/ PROCESSOR

- Volume 300ml – 1500 L

- Multiple bowl options for Drying & Processing.

- Top & bottom spray options available.

- HEPA Filtered & Humidity controlled air for drying operation.

- Improved filter bag shaking system with air purging operation

- Specially designed Conidur mesh for mechanism of Vortex formation ensuring uniform core drying.

- Advanced WIP system with multiple dynamic wash points for thorough cleaning.

- Special 12 bar design as per product.

INTEGRATED GRANULATION SUITE

- Minimal floor area consumption for installation.

- Quick product transfer & clean dust free processing at reduced expenditure.

- Suited for Potent Drug Formulation with use of advance techniques.

- Easy access to complete assembly for inspection & maintenance.

- Enclosed cleaning with advanced CIP/ WIP systems.

- Overall improvement in operational quality with separate process & technical area.

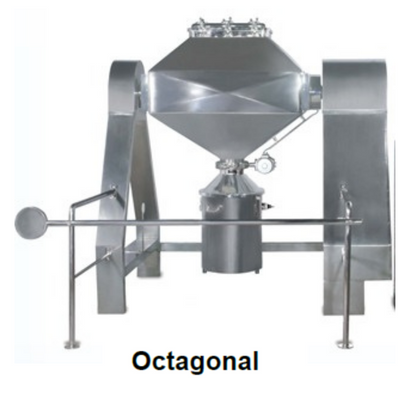

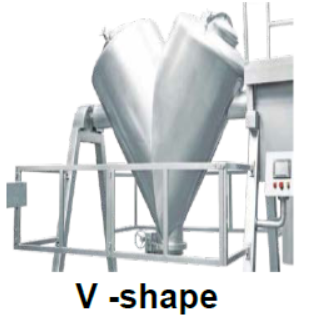

BLENDERS

- Volume- 50ml to 5000 L

- Designed for Anti-Bridging, Anti- Ratholing and separation solution.

- Interchangeable design bins available for various batch sizes.

- Smooth round edges and CMRI certified FLT brakes.

- Vacuum charging and WIP option available.

- Triclover discharge valve and triclover lid available.

- Cantilever design available for all blenders.

- Hydraulic lifting design available.

SIFTING

- Sizes available in vibro sifter from 8” to 48”

- Availability of a wide variety of screen sizes and screen types to meet the demands of many different application and processes.

- High output in rotary sifter due to centrifugal action upto 2tonnes/hr.

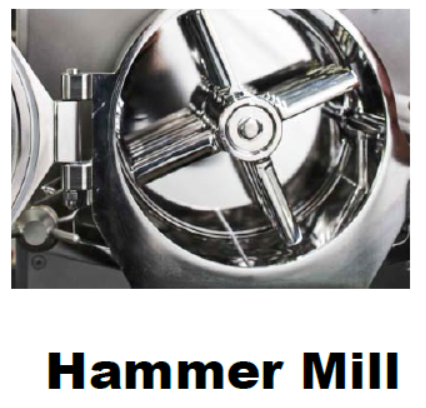

MILLING

- High throughput for maximum productivity.

- Achieve various particle size on one machine, simply by changing screen and/or impeller.

- High Speed Shredding, Sizing, Grinding and delumping of Powders, Granules, Tablets and a wide range of wet and dry materials.

- Availability for r&d as well as production scale systems.

MATERIAL HANDLING SYSTEM

- Avoids dust & contamination.

- Prevents wastage & improves yield.

- Reduces material handling & exposure of product & personnel.

- Saves time & cost.

- Available with base support.

SCISSOR LIFTS

- Stationery and mobile SS scissor lift according to application suitability.

- Customized platform sizes as per requirement.

- SS 304 matt finished structure.

- Inching + Auto mode to have floor to floor starting stopping similar to the elevator system.

- Single and multi-scissor designs to match height requirements.

- Fail-safe hose burst technology to avoid free fall in abnormal hose conditions.

- Pressure relief valve system to avoid overloading of equipment.

- Operated with a power pack with an SS enclosure.

- Lifting Load Capacity Upto-2000Kgs.

- Lifting height ranges from 0.5Mtr to 12Mtr

- AC and DC variants are available as per requirement and supply availability

POWDER TRANSFER SYSTEM

- It is an efficient, reliable method of transferring and dispensing bulk powders or bulk granules. (Sticky, fine, non-free flowing, hygroscopic, humid etc.)

- Powder can be transferred to reactor / vessel without the need to open it, hence keeping it isolated from atmosphere.

- Vessels under vacuum or pressure can be charged.

- Output ranging from 500kg /hr to 6000kg/hr depending upon product characteristic.

STARCH PREPARATION VESSEL

- Designed uniquely for optimal mixing efficiency

- Special stirrer included for homogenous mix

- Controlled temperature exposure with special jacketed bowl

- Variable rotation rate possible

- Custom-made capacity

- Direct transfer of binder solution to granulation processing equipment

- Volume is customized as per customer requirement.(50ltrs to 500ltrs).

CIP/ SIP

- Proper CIP design with regulated time, flow & temperature to thoroughly remove residue

- Custom designed to suit individual plant & application requirements along with its control systems

- Complete automated process through PLC system for Recipe type functions

- Efficient circulation of cleaning medium such as purified water, hot water, detergent solution with special provision of sanitization along with drain and flush cycles.

TABLET COATING

- Size 8” to 60“

- Suitable for both sugar and film coating

- High performance mixing baffles

- Atomizing air and pattern can be controlled independently

- Spray nozzles are Anti-bearding type

- WIP available. Easy to clean modular design

- Option of both fixed drum and interchangeable drum design.

- The discharging system is designed and engineered to discharge a single tablet from the pan without manual intervention.

CONVENTIONAL COATING PAN

- Mirror polished S.S pan ensure uniform and excellent coating of tablets.

- The thermostatically controlled heater provides regulated air upto 75oC

- Specially designed stand allows changing the tilt angle of a pan

MCD POT PROCESSOR

- Volume ranging from 1 L TO 1200 L

- Suitable for Hormonal, Oncology, Effervescent Product Processing.

- Safe production inside a closed bowl in vacuum.

- High mixing and granulation efficiency (even for low doses of active agents at < 1%)

- Low energy consumption. Drying at low temperatures.

- Easy operation and cleaning, as well as quick product changes.

- Efficient solvent recovery through cooling water.

- Small footprint with swinging bowl feature.